Latest Update on: Fiberglass Market is projected to reach $26.76 billion by 2028, at a CAGR of 6.1%

The report "Fiberglass Market by Type (Glass Wool, Direct & Assembled Roving, Chopped Strand, Yarn), Application (Composites, Construction & Infrastructure, Automotive, Glass Wool Insulation Residential, Industrial), and Region–Global Forecast to 2028" The fiberglass market was valued at USD 13.95 billion in 2017 and is projected to reach USD 26.76 billion by 2028, at a CAGR of 6.1% between 2017 and 2028. The growth of the fiberglass market is primarily triggered by the extensive use of fiberglass in the construction industry, use of fiberglass composites by the automotive industry for increased performance, and increasing number of wind turbine installations.

Browse 244 market data Tables and 49 Figures spread through 141 Pages and in-depth TOC on "Fiberglass Market – Global Forecast to 2028"

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=6124844

Chopped Strand is projected to be the fastest-growing type segment of the global fiberglass market during the forecast period.

Chopped strands are fiberglass strands that are used to provide reinforcement in the automotive and construction applications. It can be mixed with resin to produce a reinforcing gap filler in construction activities. Chopped strands used with polyester resin produces strong, stiff and tough laminates that are used in water tanks, boats, and industrial applications. They are suitable for hand lay-up process using thermoset resin systems in automobile, re-creation, chemical industries. Rising automotive production in Asia-Pacific and Europe is expected to drive the demand of the chopped strand type segment.

Composites is projected to be the fastest-growing application segment of the global fiberglass market during the forecast period.

Composites is projected to be the fastest-growing application during the forecast period. The strength-to-weight ratio of fiberglass is higher than steel and aluminum. The reduction in weight for a given level of strength makes fiberglass vital in the automotive industry. Fiberglass applications market for the automotive industry is in a developing stage, with the key drivers being low processing time and cost. A number of car manufacturers, along with glass fiber producers, are slowly venturing into the mass production of glass fiber rich automotive parts. Trends such as weight reduction, increased processing speed, and lower VOC emissions are driving fiberglass in automotive applications. Fiberglass enables automotive manufacturers to produce structural components to substitute conventional metal solutions. The applications include bumper beams, under hood applications, exterior panels, and interiors of cars and trains.

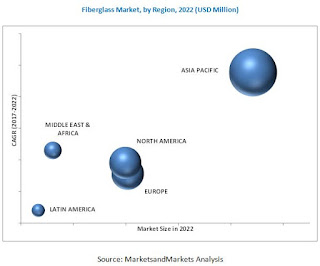

Asia-Pacific region was the largest market for fiberglass in 2017.

Asia-Pacific was the largest market for fiberglass in 2017. The increasing demand for fiberglass composites for manufacturing lightweight vehicles is driving the Asia-Pacific fiberglass market. Europe was the second largest market of fiberglass. The European Fiberglass market is mainly driven by the growing demand from the fast-growing transportation, marine, aerospace and defense, and wind energy applications. The increasing demand for fiberglass composites for manufacturing lightweight vehicles is driving the Fiberglass market.

Key players operational in the fiberglass market include China Jushi Co. Ltd (China), Owens Corning (US), PPG Industries, Inc. (US), Taishan Fiberglass Inc. (China), Chongqing Polycomp International Corp. (China), Nippon Electric Glass Co., Ltd. (Japan), and Binani 3B-The Fibreglass Company (India), Johns Manville Corp. (US), among others.

Major Drivers in Fiberglass Market:

- Extensive Use of Fiberglass in the Construction Industry

- Increased Use of Fiberglass Composites in the Automotive Industry

- Cost-Effective Production of Fiberglass in Asia Pacific

Growth in the global construction industry drives the global fiberglass market

Fiberglass is increasingly utilized in structural engineering applications, owing to its exceptional properties, such as high stiffness, high tensile strength, low weight, and high chemical resistance. Structural engineering applications include strengthening structures made of concrete, steel, timber, and cast iron. Fiberglass is also used in retrofitting of old concrete structures to increase their load capacity and flexure. The use of composite materials results in the development of lightweight and low-maintenance bridges, with high load capacity and low installation costs.

Fiberglass is a common material used in the construction of decks. Fiberglass decking is increasingly utilized in residential applications to prevent splintering, rotting, and color fading. It enhances the durability and aesthetic value of structures as compared to traditional decking.

Glass fiber rebars are used in mining and in the construction of roads and buildings, owing to their superior properties, such as high strength, flexibility, and temperature and moisture resistance. Fiberglass rebar concrete structures have an average life span of 50–60 years, with low maintenance costs, as they provide resistance to corrosion and deicing salt action, thereby enabling concrete structures to withstand harsh climatic conditions. Several infrastructure projects in the US and Canada use fiberglass rebars as concrete structure reinforcements.

Speak with our Expert @ https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=6124844

Comments

Post a Comment